Jinan Haoyang Casting & Forging Co.,ltd

Jinan Haoyang Casting & Forging Co.,ltd is one of the leading grinding media manufacturer in China .Our products are designed for grinding of raw materials by cement plants, energy generating companies, ore mining and industrial processing facilities, construction materials plants located in China . Haoyang steel balls manufacturing plant was put into operation in June 2008.Today, we deal with continuously growing consumer requirements for operational properties of grinding media, what directly affects ball mill prices and quality, efficiency of equipment and the enterprise in general. The plant was built using the most advanced equipment. Through the use of modern technologies and cooperation with a number of research organizations, we managed to achieve very high levels of quality in grinding steel balls. Despite its short history, Haoyang managed to become a manufacturer of quality grinding media for ball mills, as well to keep its position on both the domestic and...

-

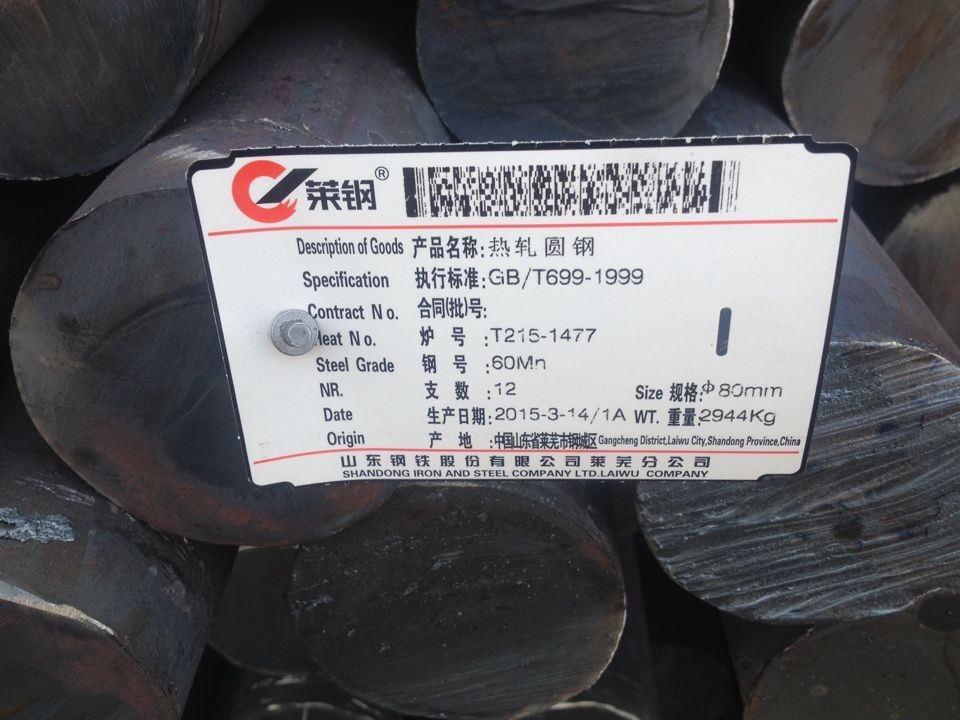

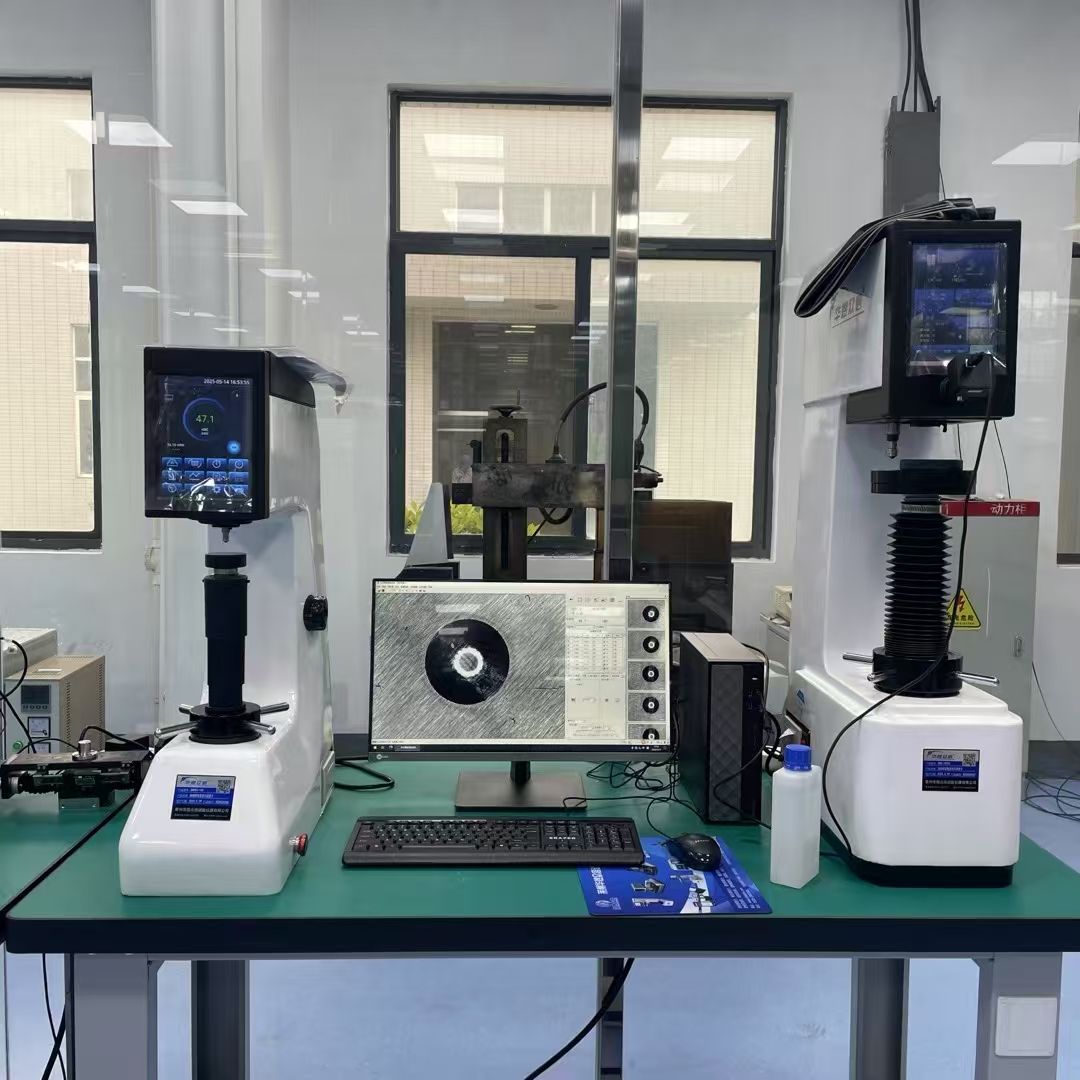

Jinan Haoyang Casting and Forging has successfully industrialized the "gradient hardening" technology, which has increased the lifespan of forged steel balls by 40%, reduced the breakage rate to less than 0.1%, and the wear of Φ60mm products per ton of raw materials is only 0.8kg. It saves 18% of electricity. This product has passed the EU REACH certification and has reached a cooperation agreement with LafargeHolcim. In the first quarter of 2025, the export volume will increase by 30%. The company plans to build a photovoltaic workshop and achieve full-process carbon neutrality production in 2026, continuously leading the high-end wear-resistant material market.

30-01-2026

Φ60mm Forged Steel Ball

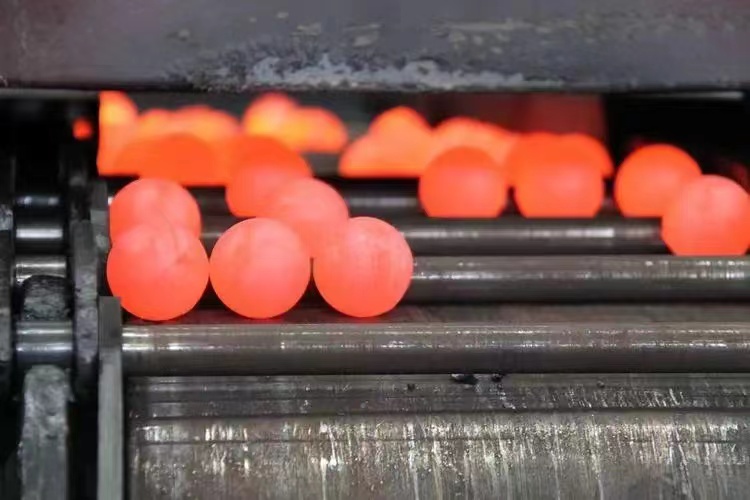

Hot-rolled Steel Balls

Hardened Forged Steel Ball

Wear-resistant Alloy Forged Steel Ball

Mill Ball

Grinding Cylpebs

Grinding Rods

Cadi Grinding Balls

High Chrome Casting Balls

Chrome Casting Balls

High Chrome Grinding Balls

Chrome Cast Balls

Sag Mill Grinding Balls

Forged Sag Mill Grinding Balls

Hot Rolling Balls

Grinding Media Balls

Grinding Balls

Forged Steel Ball

Ball Mill Balls

Grinding Balls For Ball Mill