Jinan Haoyang Forging & Casting's Brazilian customer case

Jinan Haoyang Forging & Casting's Brazilian customer case: Customized forging steel balls solve the high energy consumption problem in iron ore grinding

I. Client Background: The "Grinding Dilemma" of a Large Iron Ore Mining Enterprise in Northeast Brazil

The client is a medium-sized iron ore mining enterprise in the state of Pará, Brazil, mainly engaged in iron ore mining, processing, and export. It processes approximately 1.2 million tons of iron ore annually. Its production line is equipped with 3 Φ4.2×6.5m ball mills, and the core requirement is for efficient and wear-resistant grinding media. Previously, the client had been using domestically produced forged steel balls, which presented two major problems: Firstly, the average wear rate of 120mm steel balls was 8% per month, resulting in persistently high grinding costs per ton of ore; Secondly, the delivery cycle was as long as 45 days, frequently leading to inventory shortages.

II. Cooperation Opportunity: ISO 9001 Certification + Technical Adaptation Solution

In June 2024, the client attended the South American Mining Exhibition and noticed Jinan Haoyang Casting and Forging. The primary focus of the visit was the enterprise's ISO 9001:2015 quality management system certification (certificate number 17322Q20082R0S), confirming its stable production and quality control capabilities. Subsequently, the client expressed its core demands: the monthly wear rate of steel balls should be reduced to below 5%, and the delivery cycle shortened to within 30 days.

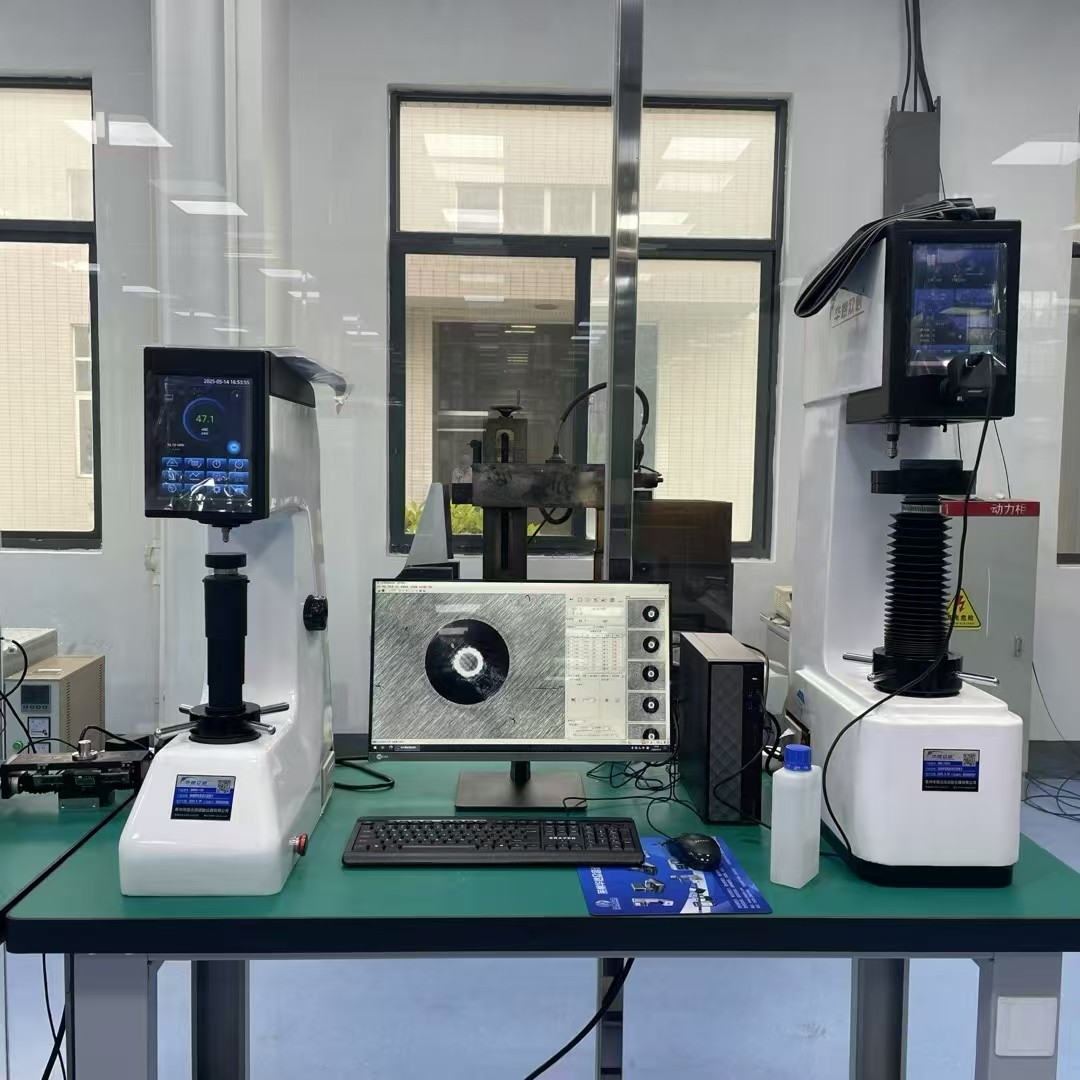

Haoyang Casting and Forging customized a technical solution based on the client's ball mill parameters and the hardness of the iron ore: using high-carbon manganese alloy steel, optimizing the density of the steel balls through a fully automatic rolling process, and then undergoing 860℃ precise isothermal quenching treatment, ensuring that the surface hardness of the steel balls is stable at 62-64HRC and the impact toughness reaches 18J/cm², precisely matching the high-strength grinding scenarios of iron ore.

III. Cooperation Implementation: From Sample Testing to Annual Supply

Sample Verification: In August 2024, Haoyang Casting and Forging sent 5 tons of 120mm customized steel balls to the client's factory. After 20 days of on-site grinding tests, the steel ball wear rate was only 4.2%, which was 46% lower than the client's original product, and no cracks or deformations were observed. It fully met expectations.

Contract Signing: In October 2024, the two parties signed a half-year supply contract, stipulating that 30 tons of 120mm forged steel balls would be supplied monthly, transported via Qingdao Port - São Luís Port in Brazil, relying on the client's port storage to achieve "order placement in the current month, delivery in the next month", with the delivery cycle compressed to 25 days.

After-sales Guarantee: Based on the requirements of the ISO 9001 system, Haoyang Casting and Forging provided the client with "quality inspection report for each batch + 72-hour after-sales response" services. In case of any quality issues, solutions would be provided within 48 hours to ensure production continuity.

IV. Cooperation Results: Cost Reduction and Market Expansion Win-Win

Client Benefits: Within half a year of the cooperation, the client's grinding cost per ton of ore decreased from 23.5 Brazilian reals to 15.8 Brazilian reals, saving approximately 450,000 reals (equivalent to 680,000 RMB), with the frequency of ball mill shutdown for material replenishment reducing from 3 times per month to 1 time, and production efficiency increasing by 12%.

Enterprise Breakthrough: In April 2025, the client renewed the contract as an annual contract, increasing the supply volume to 40 tons per month, and recommending 2 Brazilian iron ore enterprises to connect with Haoyang Casting and Forging, helping the enterprise establish a "technically reliable, service-efficient" brand perception in the South American market.