Heat Treated Grinding Rods

- HY

- China

- 20-45 days

- 50000T

Our Forged Grinding balls produced by advanced automatic rolling machine ( Balls from 20mm-70mm) + Labor Air Hammer ( 80mm-150mm) with special Heating treatment and strict quality control systerm , which make our grinding balls high performance

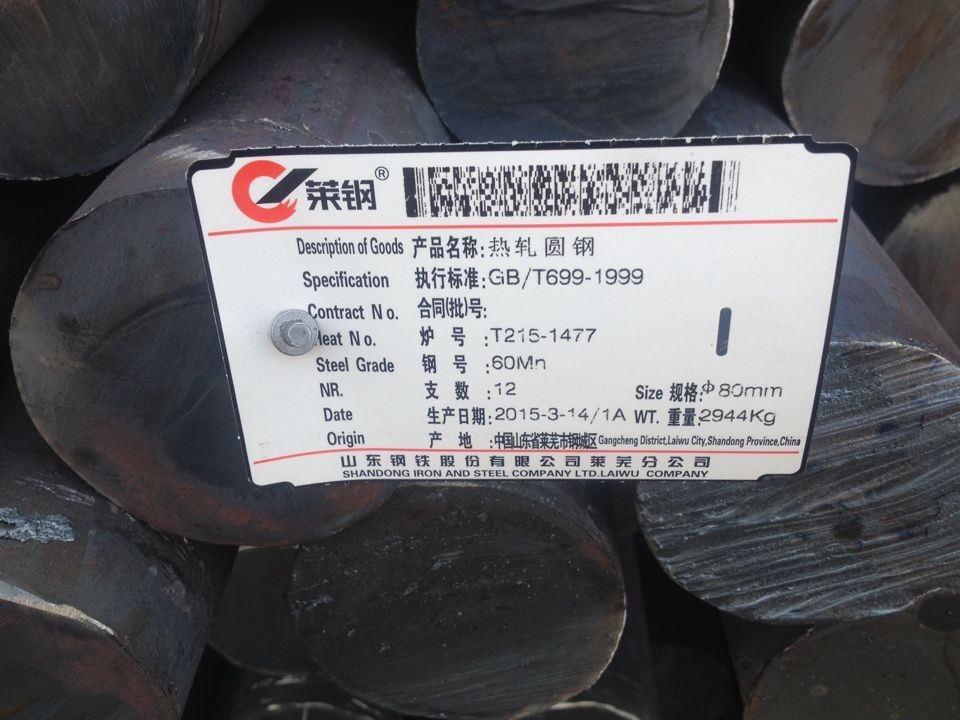

Grinding balls 'Raw Material Purchase : Strategic partnership with standard steel enterprise and sign the long term agreement (50,000 Tons annually ) Purchase directly from Chinese famous standard steel enterprise , such as laigang Group, HBIS, ANSTEEL, XIWANG Special steel .

We have special department of QC teamwork .The QC department director have 10 years experience in this industry . The team is responsible for inspection during production , inspection before delivery .( Forged Steel Grinding balls Surface and core hardness test each day each batch and all will be recorded and filed in documents ) .

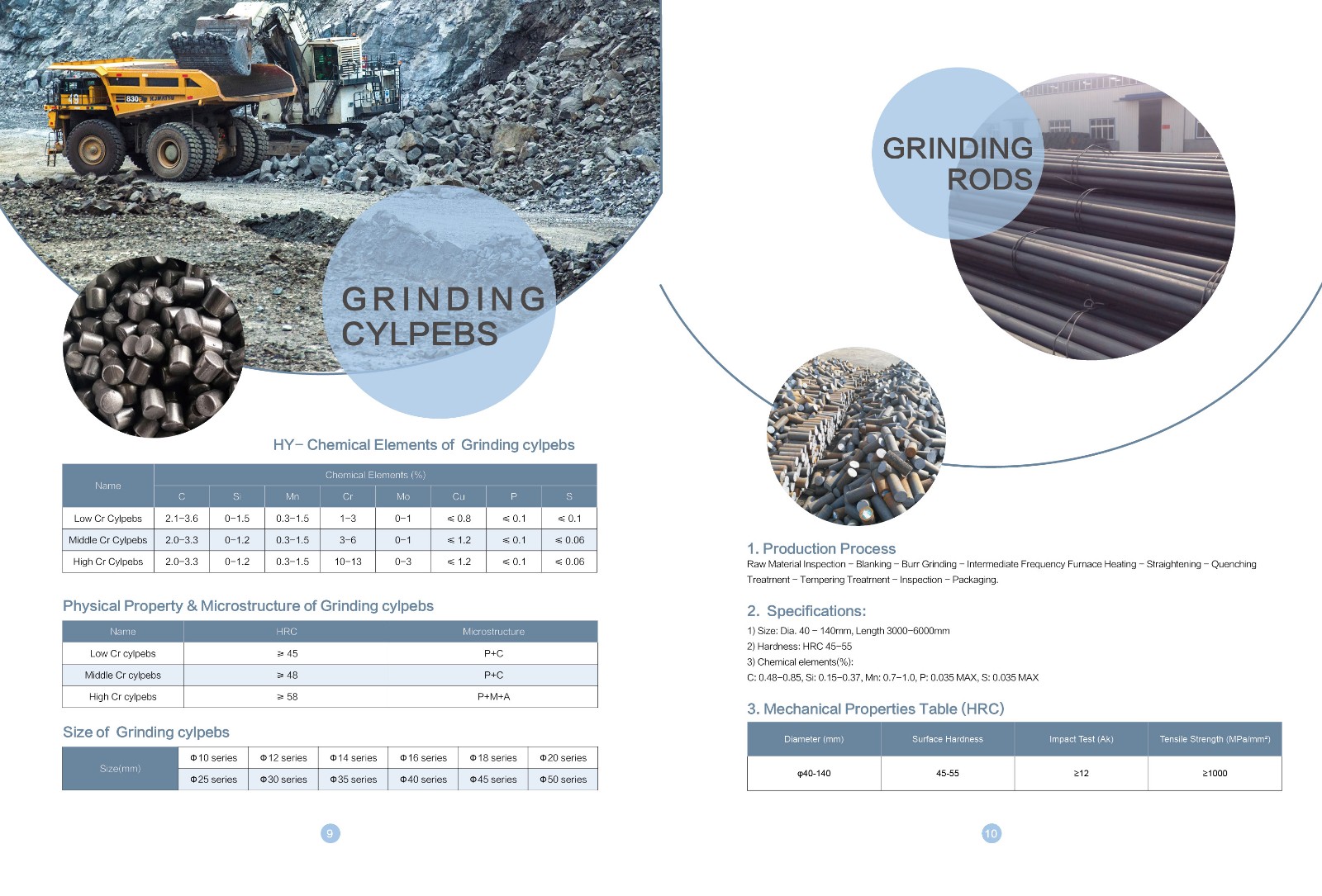

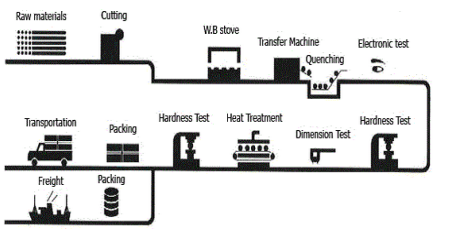

HY Grinding Rods Production process :

Raw Material inspection --Blanking--Burr Grinding--Intermediate Frequency Furmace Heating-- Straightening --Quenching Treatment-Tempering Treatment--Inspection--Packaging

Specification:

1) Size: Dia40-140mm Length 3000-6000mm

2) Hardness: HRC 45-55

3) Chemical elements(%)

C. 0.48-0.85 Si: 0.15-0.37 Mn: 0.7-1.0 P: 0.035MAX S: 0.035MAX

Mechanical Properties Table (HRC)

Diameter (mm) | Surface Hardness | Impact Test ( Ak) | Tensile Strength (MPa/m㎡) |

¢40-140 | 45-55 | ≥12 | ≥1000 |

Ball Milling The Grinding Balls are produced from High Carbon or Alloy steel bars and then forged into balls or by Auto rolling machine improving the output.which are for use in mineral processing ball milling operations . Using the high carbon content and high hardness levels for maximum abrasion resistance . in nominal sizes from 1.0” to 4.0” in diameter.2. SAG Milling Haoyang Balls range has some of the leading SAG ball products in the industry, that are specifically designed for today's SAG milling environments. Haoyang has developed a product with high toughness and superior wear life.3. Ball Milling for Industrial Applications Haoyang manufactures grinding balls for use in industrial applications such as power and cement. The balls are manufactured from high carbon, alloy steel bars and then forged into balls.

Raw Material Quality Guarantee

Haoyang has established strategic relationships with our local steel plant or supplier allow us to guarantee all the grinding balls supplied to our customers are made from the highest quality steel and meet strict specifications. Each batch of balls will be recorded via Steel Heating Number for the following track.

Forged Grinding balls chemical composition :

Brand | Remarks | Chemical Composition (%) of Raw Material | ||||||

C | Mn | Cr | S | P | Si | Hardness | ||

HY-1 | 60Mn | 0.57-0.65 | 0.7-1.0 | 《0.25 | Max0.030 | Max0.030 | 0.17-0.37 | 58-60 |

HY-2 | 65Mn | 0.60-0.70 | 0.90-1.2 | 《0.25 | Max0.030 | Max0.030 | 0.17-0.37 | 58-65 |

HY-3 | 75Mn | 0.72-0.92 | 0.90-1.2 | 《0.25 | Max0.030 | Max0.030 | 0.17-0.37 | 55-65 |

HY-4 | B2 | 0.72-0.85 | 0.7-1.2 | 0.42-0.85 | Max0.030 | Max0.030 | 0.17-0.37 | 60-65 |

HY-5 | B3 | 0.5-0.65 | 0.4-1.0 | 0.77-1.10 | Max0.030 | Max0.030 | 1.4-1.8 | 60-65 |

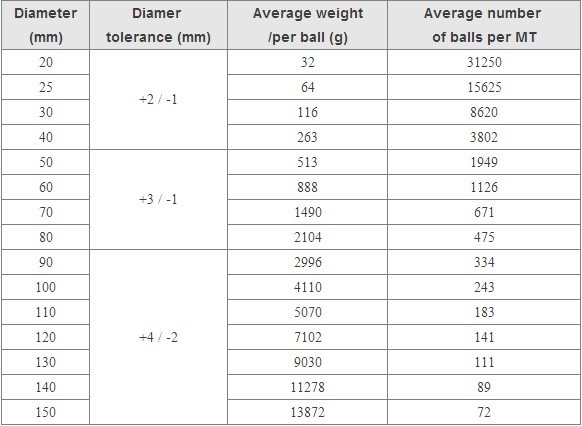

Dimension Series :

Grinding balls Production Process :

Packing of Grinding Media Balls

The grinding balls to be packed in steel drums with openable top or bulk bags. The plastic bags should be of good quality with 5:1 safety ratio. Drums or bags packed on pallets made of heat treated wood or plywood.