Produce Cheap Grinding Steel Balls For Gold Mining Factory

- HY

- China

- 20-45 days

- 50000T

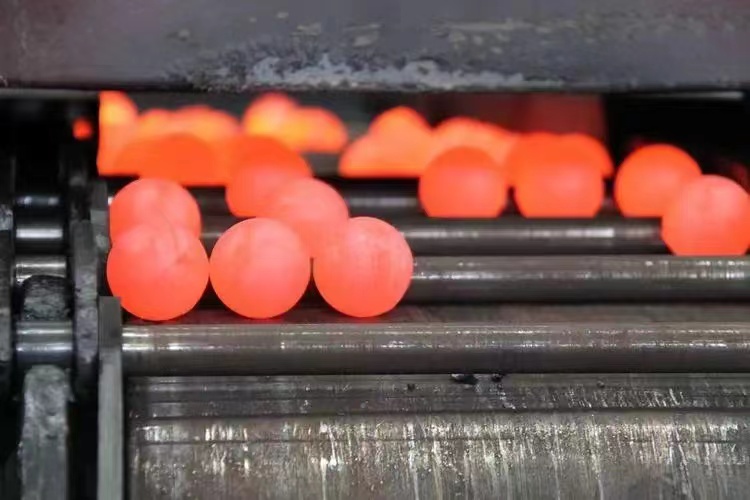

Our Grinding balls produced by advanced automatic rolling machine ( Balls from 20mm-70mm) + Labor Air Hammer ( 80mm-150mm) with special Heating treatment and strict quality control systerm , which make our grinding balls high performance

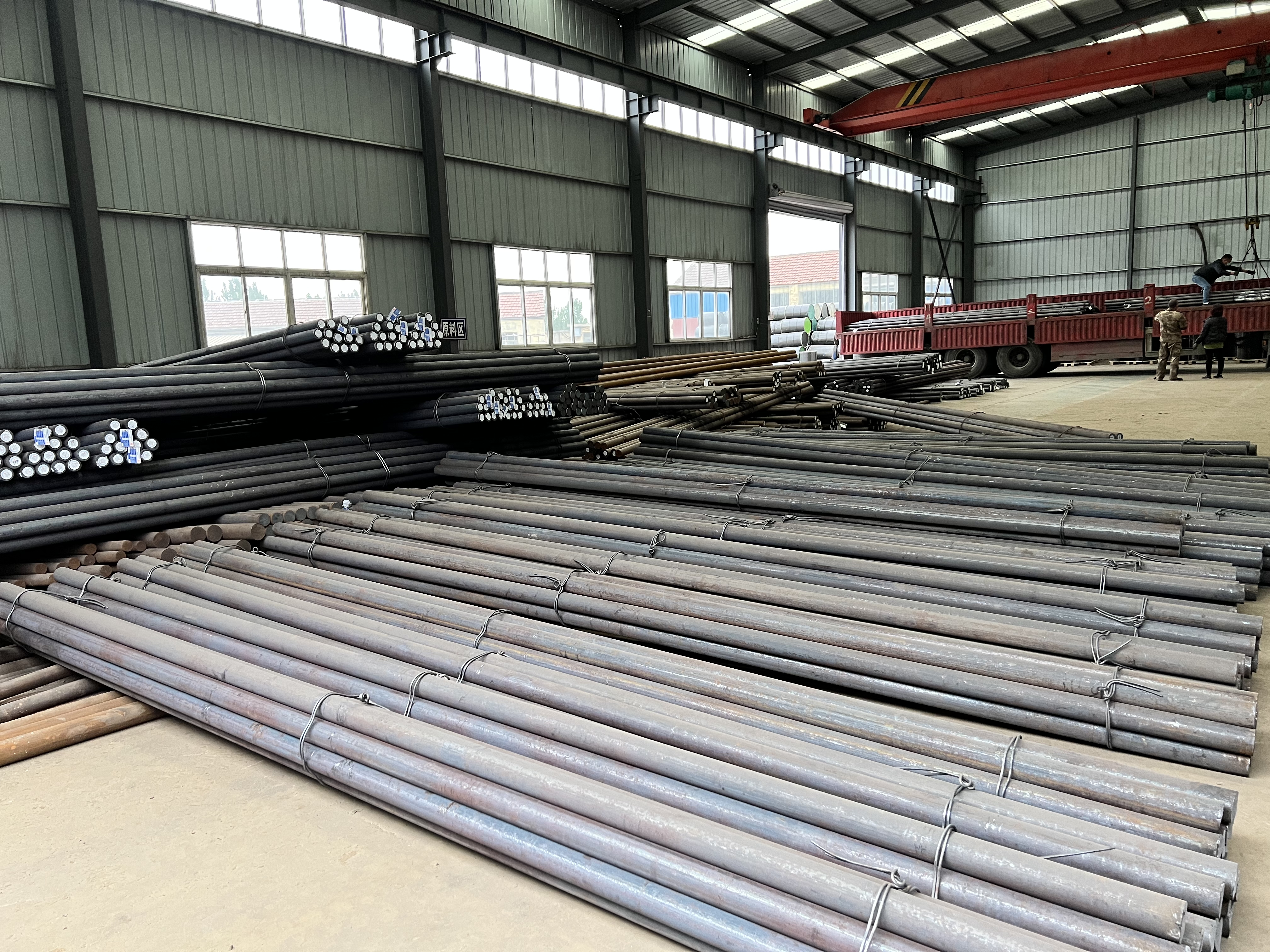

Grinding media balls 'Raw Material Purchase : Strategic partnership with standard steel enterprise and sign the long term agreement (50,000 Tons annually ) Purchase directly from Chinese famous standard steel enterprise , such as laigang Group, HBIS, ANSTEEL, XIWANG Special steel .

We have special department of QC teamwork .The QC department director have 10 years experience in this industry . The team is responsible for inspection during production , inspection before delivery .( Grinding balls Surface and core hardness test each day each batch and all will be recorded and filed in documents ) .

Produce Cheap Grinding Steel Balls For Gold Mining,Grinding steel balls Factory

HY specialize in the grinding steel balls industry for about 30 years and provide the best service for Gold mining ,copper mining and cement plant . The grinding balls are the means to crush or grind material ( mineral, coal or cement ) in the ball mill. So the grinding steel balls have different size and produced with different alloy steel under the working condition .

Haoyang Forging has signed the largest single steel ball order in Southeast Asia, setting a new record for export volume.

Release Date: December 8, 2024

Today, Jinan Haoyang Forging Co., Ltd. signed a 23,000-ton supply contract for wear-resistant steel balls with an Indonesian nickel mine group. The total amount is 110 million yuan, setting a new record for the company's single export order. These φ120mm low-alloy steel balls will be used in the new 5 nickel ore beneficiation production lines of the other party. The delivery is expected to start in batches in March 2025.

In response to the high temperature and high humidity conditions in Southeast Asia, the company has specially developed weather-resistant steel balls. By adjusting the ratio of chromium and molybdenum alloys, the products can maintain an impact toughness of 12J/cm² even in environments above 60℃. "To meet the delivery requirements of the orders, we will activate the newly-built intelligent warehousing center. This center is equipped with 2,000-level shelves and AGV handling robots, which can achieve fully automated storage and sorting of steel balls, and the logistics efficiency will be increased by 40%." The manager of the International Trade Department introduced.

This order represents a significant breakthrough for the company's "deeply engaging in the Belt and Road Initiative" strategy. Currently, the Southeast Asian market has become the company's second-largest overseas market, accounting for 38% of its total exports. In 2024, the company's export business is expected to increase by 65%, and it is projected that the total import and export volume for the entire year will exceed 180 million yuan, representing a 52% increase compared to the previous year.