Green forged steel balls, with a 100% recycling rate of scrap steel.

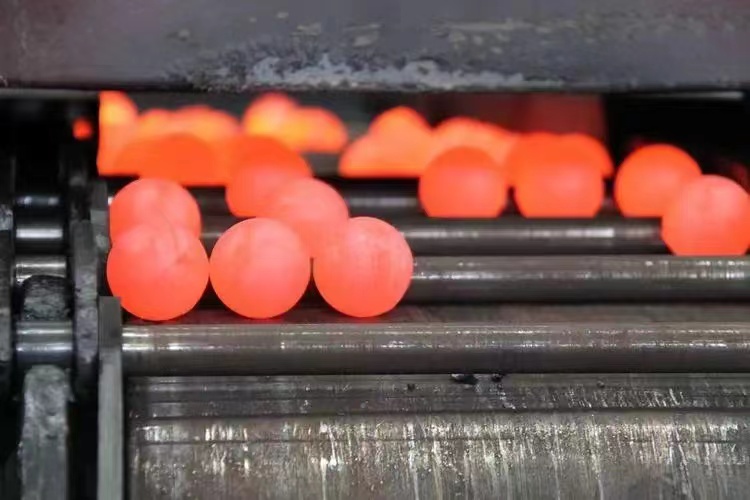

In January 2026, Haoyang Casting and Forging of Jinan launched gradient-hardening forged steel balls. The surface hardness is 65HRC, the toughness is 18J/cm², and the lifespan has been increased by 40%. The unit consumption is 0.5kg/t of raw ore. Using the 42CrMoV alloy and medium-frequency heating technology, it obtained a national patent. The first batch of 2,000 tons of orders will be supplied to BHP Billiton. The annual production capacity is 30,000 tons. A digital twin workshop is planned to be built, with the goal of achieving a 40% market share in the high-end market.

In January 2026, Jinan Haoyang Forging & Casting Co., Ltd. launched a new generation of "gradient hardening forging steel balls". Through the independently developed "nanocrystalline carbonization precipitation" process, it achieved a double breakthrough in surface hardness of 65HRC and core toughness of 18J/cm². The product lifespan was increased by 40% compared to traditional processes, and its wear resistance reached the international leading level. This technology has been granted a national invention patent. The first batch of 2,000 tons of orders will be supplied to the BHP Billiton iron ore project in Australia.

As a specialized, innovative, distinctive and high-quality enterprise in Shandong Province, Haoyang Casting and Forging has recently launched a full range of steel balls with diameters from 40mm to 120mm. These steel balls are made of 42CrMoV alloy and are heated by medium-frequency induction technology. After being tested by the National Quality Supervision and Inspection Center for Casting and Forging Machinery, the impact toughness is ≥ 15J/cm², and the single consumption has been reduced to 0.5kg/t of raw ore, which is 30% lower than that of imported products. "In an industrial trial at a gold mine in Shanxi Province, the 80mm steel balls operated continuously for 1200 hours without any fractures, setting a new industry record," said Engineer Li, the director of the company's R&D department. This technology will reduce the cost of grinding media in mines by 15% to 20%.

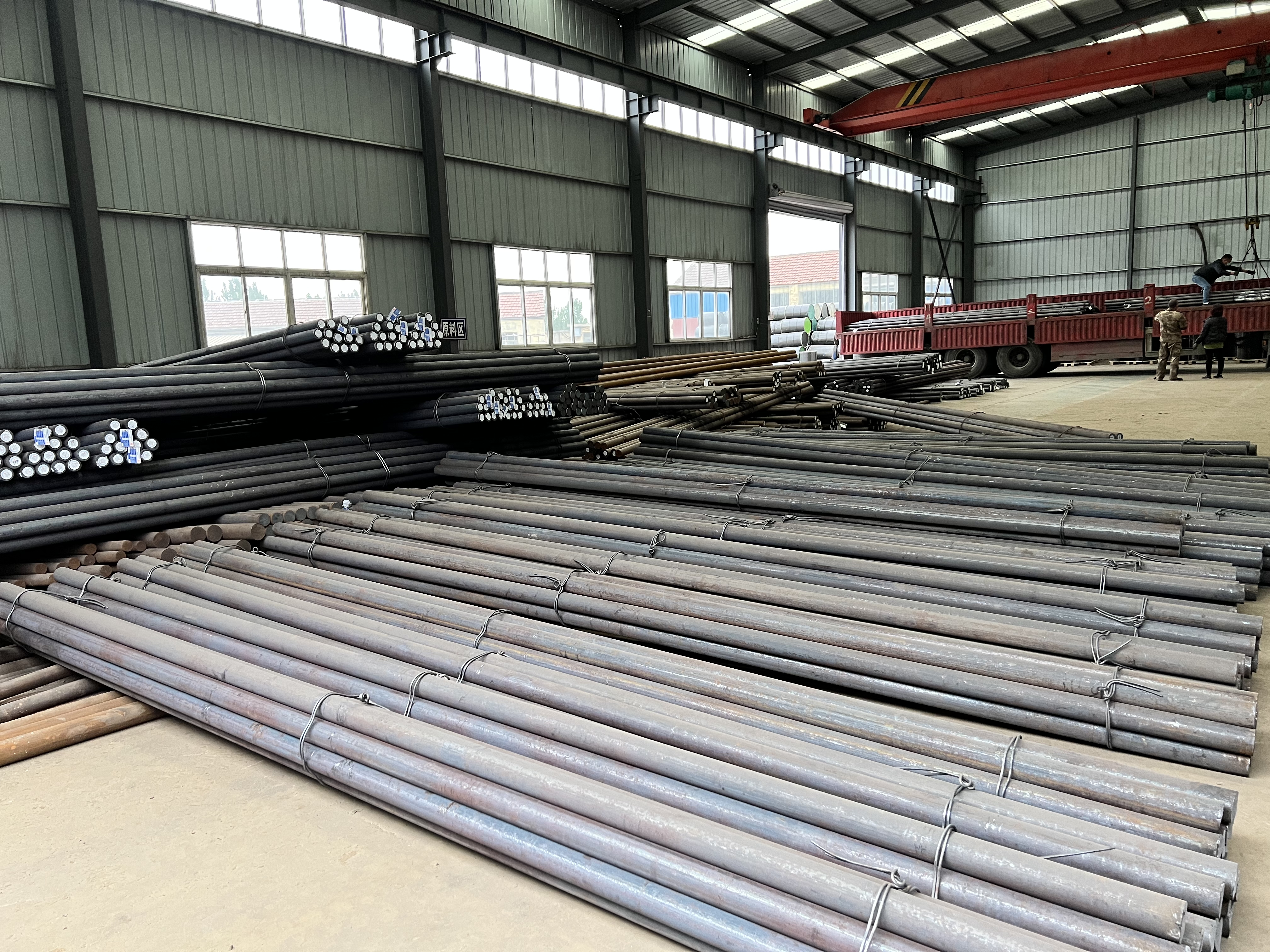

Currently, the intelligent production line of Haoyang Forging has an annual production capacity of 30,000 tons. The products have been included in the supply chains of leading enterprises such as Zijin Mining and Tongling Copper. In 2026, it plans to invest 50 million yuan to build a digital twin forging workshop, with the goal of achieving a market share of over 40% in the high-end market.