Ball Mill Grinding balls introduction

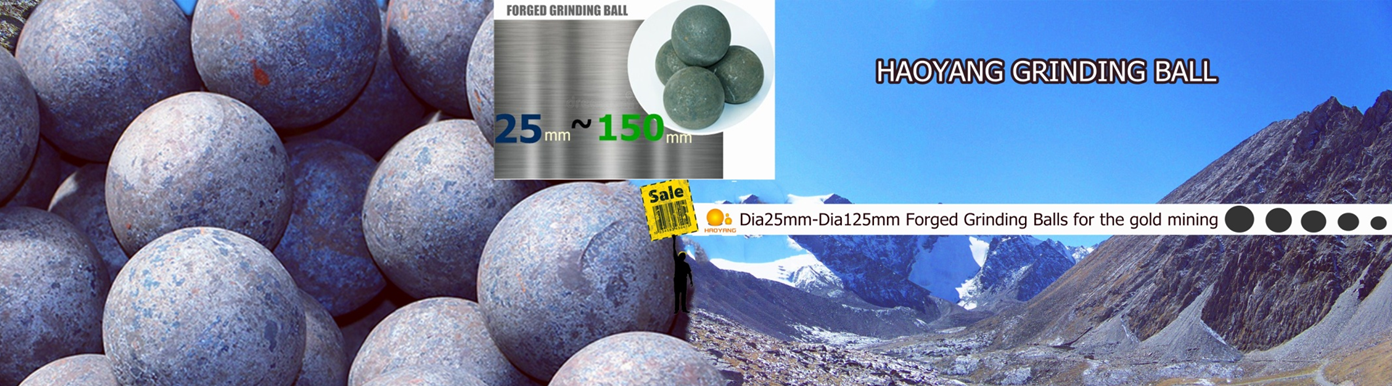

HAOYANG GRIDING BALLS FOR BALL MILL

Haoyang Grinding ball is a kind of common medium,widely used in cement,metal mining,power plant and chemical industry etc.We are China reliable grinding ball manufacture and supplier for more than 15 years.the type of balls is forged steel ball and cast iron ball.Ball mill grinding media balls could porvide services for some mining companies all over the word,to win our customer’s trust by excellent quality and profession。We can supply tailor-made grinding media to our customers.

In recent years, with the upsizing of ball mills worldwide and the increasing use of large ball mills in mines, there is a great demand for large-diameter wear-resistant steel balls, and the demand is increasing year by year. The main advantage of using large-diameter wear-resistant steel balls is to improve the grinding efficiency.Wear resistant steel ball in production loss is very large, in the process of use in the ball mill by repeated impact and material extrusion, so the macro failure of large diameter ball mainly wear, peeling, out of round, broken, etc..Before, austenitic manganese steel, low alloy steel casting ball, chromium alloy cast iron ball, wear-resistant cast iron and other wear-resistant materials in industrial production is more common, but have not been able to well solve the hardness and toughness of grinding ball, hardenability and alloy element content of these two contradictions.Hardness is usually high and low toughness, high crushing rate;The high content of alloy elements improves the hardenability, but increases the cost.

Through the production practice and continuous test, we can get: compared with the casting ball, the forging steel ball has the main characteristics of fast forging speed, high output, good shape and smooth surface.Forging steel ball compression is larger, the inner structure of grinding ball compactness is better.Forging grinding ball of high hardness, good toughness, not broken.Forging steel ball greatly reduces the use of chromium, reduces the pollution to the environment, instead of casting ball suitable for the use of wet grinding in mines.The forging steel ball of high carbon and low alloy steel is produced by the process of forging residual heat quenching.The heat treatment process can optimize the structure of steel and improve the mechanical properties of steel, which plays a very important role in the normal use of the material.

The forging steel ball with simple production process, low cost, good wear resistance and low crushing rate has become the target of people's pursuit.

HAOYANG ball mill forged grinding media balls are used in mining or grinding processes to crush

This grinding medium is made of steel and cast iron. Manufacturing method. Recently, the manufacturers of stamping balls have lost their relevance in the market because this method is quite energy intensive, which leads to higher cost of finished products. Molding is the second method of producing cost finished products. It's basically a ball of cast iron. This type of grinding ball is also very expensive to produce. In addition to energy consumption, a large proportion of "waste" in production will also affect the cost of finished products. At present, the most competitive ball production technology is the spiral rolling of round billet. For small enough energy consumption in production, the amount of "waste" is less than 1-1.5% of the total amount of raw materials.